Blog

High Tech Manufacturing Machinery Solutions Redefining Industry Excellence

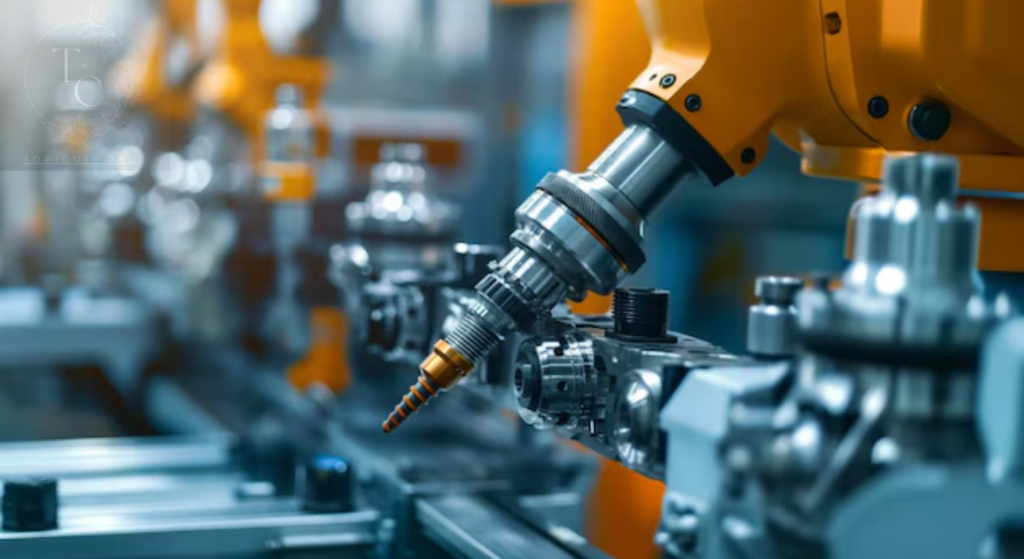

In the modern era of production, precision and efficiency define success. High tech manufacturing machinery solutions empower industries to meet these demands with cutting-edge technology, streamlining operations, and driving innovation. Businesses leveraging these advanced solutions can achieve unparalleled productivity, quality, and competitiveness.

Why High Tech Machinery is Essential for Manufacturing

Manufacturing requires precision, speed, and consistency, making advanced machinery an integral part of modern operations. High tech manufacturing machinery solutions provide the automation and intelligence necessary to meet evolving market demands while maintaining quality standards.

From assembly lines to packaging processes, these solutions reduce human error, optimize resource utilization, and minimize downtime. They also allow manufacturers to scale operations without compromising efficiency, ensuring they stay ahead in a competitive landscape.

Features of High Tech Manufacturing Machinery Solutions

Understanding the unique features of high tech manufacturing machinery solutions reveals why they have become indispensable across various industries.

Automation for Streamlined Operations

Automated systems eliminate manual intervention in repetitive tasks, reducing errors and accelerating production. This feature ensures consistent output and frees employees to focus on more strategic responsibilities.

Precision Engineering for Quality

Advanced machinery delivers unmatched accuracy, ensuring every product meets exact specifications. This precision reduces waste, minimizes rework, and upholds quality standards.

Real-Time Monitoring and Data Analytics

Many high-tech solutions come equipped with sensors and data analytics capabilities. Real-time monitoring allows manufacturers to track performance, identify inefficiencies, and make data-driven decisions to enhance productivity.

Customization and Flexibility

Modern machinery adapts to various production requirements. Manufacturers can customize equipment configurations and settings to accommodate specific needs, providing flexibility in operations.

Integration with Smart Systems

The integration of high tech manufacturing machinery solutions with IoT and smart factory technologies enables seamless communication between machines. This connectivity enhances coordination and efficiency across the production line.

Applications of High Tech Machinery Across Industries

The versatility of high tech manufacturing machinery solutions allows their implementation in diverse sectors. Each industry benefits uniquely from these advanced systems, transforming its production capabilities.

Automotive Manufacturing

In the automotive industry, precision and efficiency are paramount. High-tech machinery automates assembly lines, ensuring seamless production of vehicle components and reducing lead times. Robotics also enhance safety by handling hazardous tasks.

Pharmaceutical Production

Pharmaceutical companies rely on advanced machinery for precise formulation, packaging, and labeling. These systems maintain stringent quality control and comply with regulatory standards, ensuring patient safety and product reliability.

Food and Beverage Industry

High-tech solutions streamline food processing and packaging, ensuring hygiene and consistency. From automated filling machines to robotic sorters, these technologies optimize operations while meeting consumer demands for quality.

Electronics Manufacturing

In electronics, where miniaturization and precision are critical, high-tech machinery enables accurate assembly of circuit boards and components. Automation reduces defects and supports high-volume production with minimal downtime.

Textiles and Apparel Production

Modern machinery revolutionizes textile manufacturing by automating weaving, dyeing, and cutting processes. This efficiency reduces waste and enhances customization options, catering to diverse consumer preferences.

Benefits of Investing in High Tech Machinery

The adoption of high tech manufacturing machinery solutions offers transformative benefits for businesses. These advantages position manufacturers for long-term success in an increasingly competitive market.

Enhanced Productivity

Automated systems accelerate production cycles, enabling manufacturers to meet high demand without sacrificing quality. This boost in productivity supports scalability and profitability.

Cost Efficiency

Although high-tech machinery requires upfront investment, it reduces operational costs in the long run. Energy-efficient systems, minimized waste, and reduced labor expenses contribute to significant savings.

Consistent Quality Standards

Maintaining consistent quality is crucial in manufacturing. Advanced machinery ensures uniformity across production batches, meeting customer expectations and minimizing product recalls.

Reduced Downtime

Predictive maintenance features detect potential issues before they disrupt operations. This proactive approach minimizes downtime, keeping production schedules on track and avoiding costly delays.

Environmental Sustainability

Energy-efficient machinery reduces resource consumption and lowers carbon emissions. This sustainability aligns with global efforts to combat climate change, enhancing the brand’s reputation among eco-conscious consumers.

How to Choose the Right High Tech Machinery

Selecting the best high tech manufacturing machinery solutions requires careful consideration of specific business needs and operational goals. Here’s how to make the right choice:

Assess Production Requirements

Identify key production challenges and areas where automation or precision can deliver the most impact. Focus on solutions that address these needs effectively.

Evaluate Scalability

Choose machinery that can grow with your business. Scalable systems accommodate future expansion, ensuring long-term value for your investment.

Prioritize Compatibility

Ensure the machinery integrates seamlessly with existing systems and infrastructure. Compatibility reduces implementation challenges and supports efficient operations.

Consider Total Cost of Ownership

Look beyond upfront costs to evaluate long-term value. Consider maintenance, energy consumption, and potential savings when assessing total cost of ownership.

Research Vendor Support

Partner with vendors offering reliable support, training, and maintenance services. Strong partnerships ensure optimal performance and longevity of your machinery.

Overcoming Challenges in Adopting High Tech Solutions

While high tech manufacturing machinery solutions offer immense benefits, their adoption comes with challenges. Proactively addressing these issues ensures successful implementation:

Resistance to Change

Employees may resist automation due to concerns about job security. Transparent communication and training programs help ease transitions and empower workers to adapt.

High Initial Costs

Investing in high-tech machinery requires significant capital. Explore financing options or phased implementation to manage costs effectively.

Integration Complexity

Integrating new machinery into existing systems can be complex. Collaborate with experienced vendors and consultants to streamline the process and minimize disruptions.

Skills Gap

Operating advanced machinery requires specialized skills. Invest in training programs to equip employees with the knowledge needed to manage and maintain high-tech systems.

The Future of High Tech Manufacturing Machinery

As technology evolves, high tech manufacturing machinery solutions continue to unlock new possibilities. Emerging trends promise to redefine the future of manufacturing:

Artificial Intelligence and Machine Learning

AI-driven machinery learns from data to optimize production processes, predict maintenance needs, and improve decision-making. This innovation enhances efficiency and reduces costs.

Collaborative Robotics

Cobots work alongside humans to handle repetitive tasks while employees focus on strategic roles. These robots improve productivity without replacing the human workforce.

Advanced 3D Printing

High-tech 3D printers enable rapid prototyping and on-demand production of complex components. This technology reduces lead times and supports customization.

Sustainable Manufacturing Solutions

Energy-efficient machinery and eco-friendly materials support sustainable production practices. These advancements reduce environmental impact and align with global sustainability goals.

Embrace the Future of Manufacturing

High tech manufacturing machinery solutions are not just tools—they are catalysts for growth, efficiency, and innovation. By embracing these technologies, businesses can achieve operational excellence, reduce costs, and maintain a competitive edge.

Investing in advanced machinery today prepares industries for the demands of tomorrow. With the right strategies and partnerships, manufacturers can unlock new opportunities and redefine what’s possible in modern production.